The Secret to Healthier Plants &

Less Maintenance

PRIMARY FILTRATION SYSTEMS

The Secret to Healthier Plants & Less Maintenance

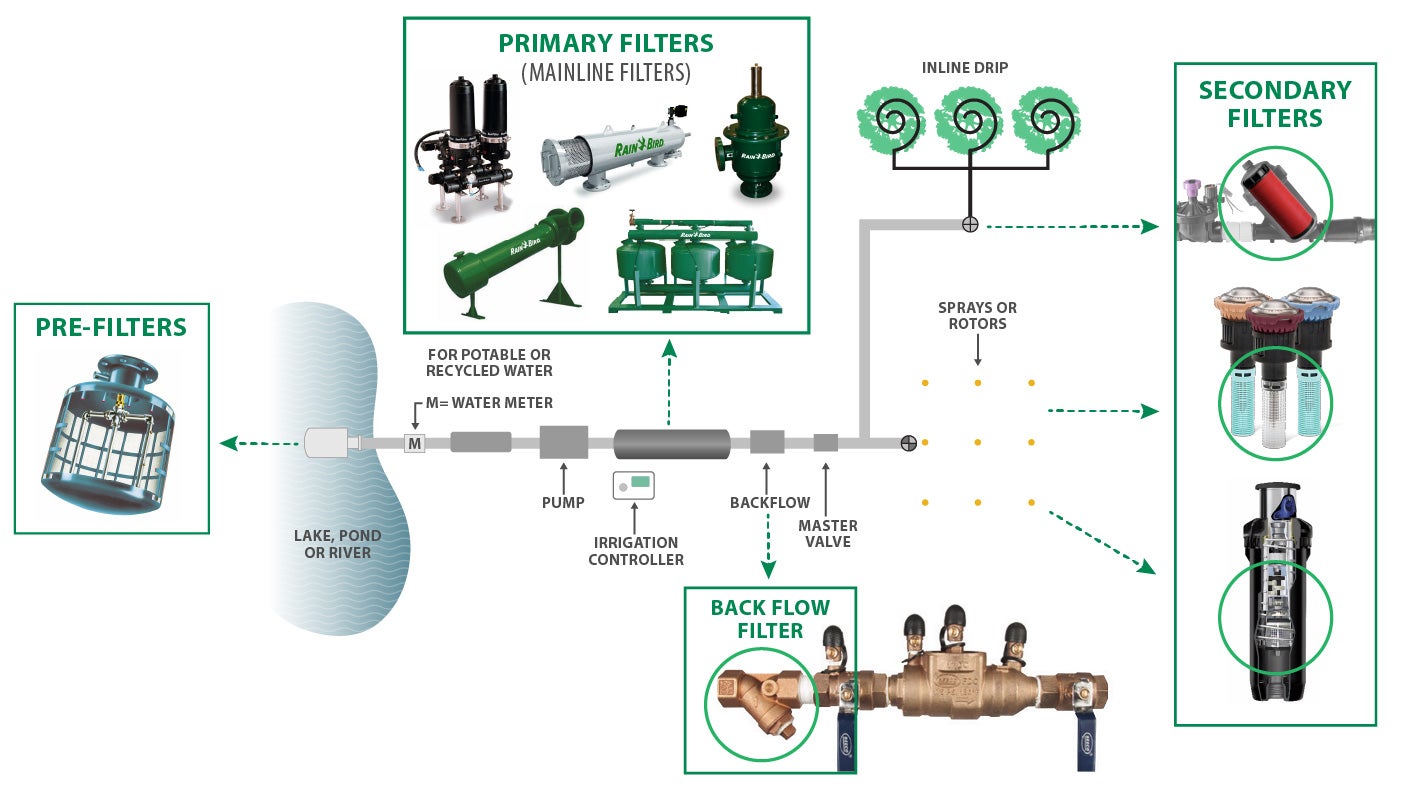

What is a Primary Filtration System?

A Primary Filter, also known as a “Mainline Filter” or "Irrigation Filter," is the first line of defense against contaminants in an irrigation system. Primary filters should not be confused with "backflow filters" or "Y strainers," since they are added in addition to backflow preventers.

When to Add Primary Filtration

Primary Filtration is not just for alternative water sources. Every irrigation system can benefit from primary Filtration —even those fed by municipal supply lines. Oxidation in aging steel pipes, for example, can flake off and clog nozzles. Breaks in the municipal supply line can allow damaging debris into your system. Adding primary Filtration is always a smart choice.

Primary Filtration is Beneficial for:

Municipal Water Pipe

Ground Water Well

Natural and Manmade Bodies of Water

Reclaim Pond/Cistern

Waste Treated Water

Prevent Clogs Caused By:

Significant Savings with Primary Filtration

Without a primary filter in place, contaminants move down the line and pile up at each individual emission device. Not only does this lead to hours of time spent repairing broken filters and checking for clogged heads, but it also prevents plant material from receiving the correct amount of water. Primary Filtration stops sediment at the source—long before it causes exponential damage downstream.

|

Save TimeReduce downstream maintenance at each individual device |

|

Save MoneyIncrease efficiency and extend the life of irrigation equipment |

|

Save WaterMaximize the performance of all emission devices |

|

Save PlantsMaintain distribution uniformity and keep landscape healthy |

Why Secondary Filtration is Not a Substitute for Primary Filtration

Back Flow Filter (Y Strainer)

-

Not customizable to specific filtration needs (Algae, Sand, Calcium & Non-Potable)

-

Not self-cleaning

-

More maintenance than Primary Filtration

-

Such a small footprint it will need to be cleaned often

-

Difficult to access and service

-

Cross connection issues on reclaimed systems

-

Limited mesh/micron sizes

Manual Low-Flow Filters

-

Single valve filter (rather than total system solution)

-

Filters downstream of the valve (no filtration for the valve or anything upstream)

-

Better used as a secondary catch in the event of a break rather than the primary filtration source

-

Has limited flow capacity

-

Not self-cleaning (manually cleaned and often many units on a single system)

-

Not very customizable for water types

-

Not very customizable for emission devices

The Real Game Changer: Self-Cleaning Filters

Unlike secondary filters, primary filters do not need constant cleaning and manual maintenance. This can reduce required maintenance by upwards of 50%! Additionally, if secondary filters are not properly maintained, plant material will die due to clogged emission devices and improper watering. Primary filters make the most of tight maintenance budgets while keeping irrigation systems functioning at peak performance.

SAMPLE SCENARIO

Park Maintenance Costs Without a Primary Filter:

|

The average park likely has around 350 secondary filters to clean & maintain. For this exercise, assume these filters are only cleaned once a month. 350 filters x 3 min per filter = 1,050 min. 1,050 minutes/60 = 17.5 hours per month. |

See a Self-Cleaning Primary Filter in Action

How to Specify a Primary Filter

A primary filter must be specified for your unique needs. Consider the following when specifying or ordering a primary filter for your system:

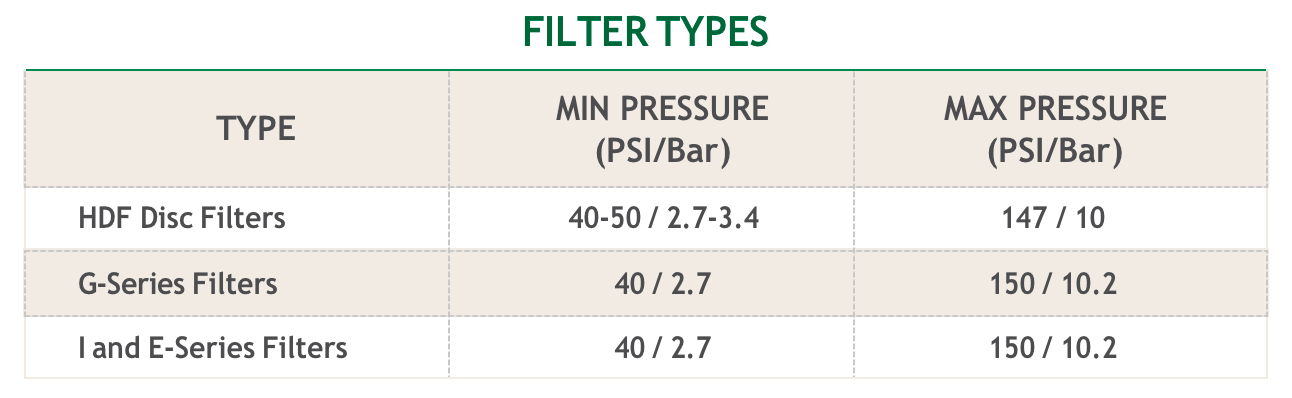

Your mainline will be one of these common trade sizes: 2", 3", 4", 6", 8", 10" or 12." Otherwise, you can also measure the circumference of the pipe and divide by 3.14, then round down to the next whole number to find the inside diameter.

Self-cleaning filters require a minimum operating pressure while flushing mechanism is engaged.

Just like any irrigation equipment, we need to account for your system's highest and lowest flows. Always consider maximum flow when running multiple stations at a time.

Although your system may only have flows up to 100 GPM, we may specify a filter that can handle much more.

Why would we do this? There are two factors that affect the rate at which water can flow through the filter:

- Water Source Quality

- Micron Size

Rain Bird will determine the best fit for you. However, the example below shows the variation in flow rates based on micron size and water source for this specific model of filter (HN-G-02).

Most applications will follow the Average, Poor, or Very Poor lines. You always want to select a filter that can accommodate a greater water flow than the system is expected to see.

Flow Capabilities Example for HN-G-02

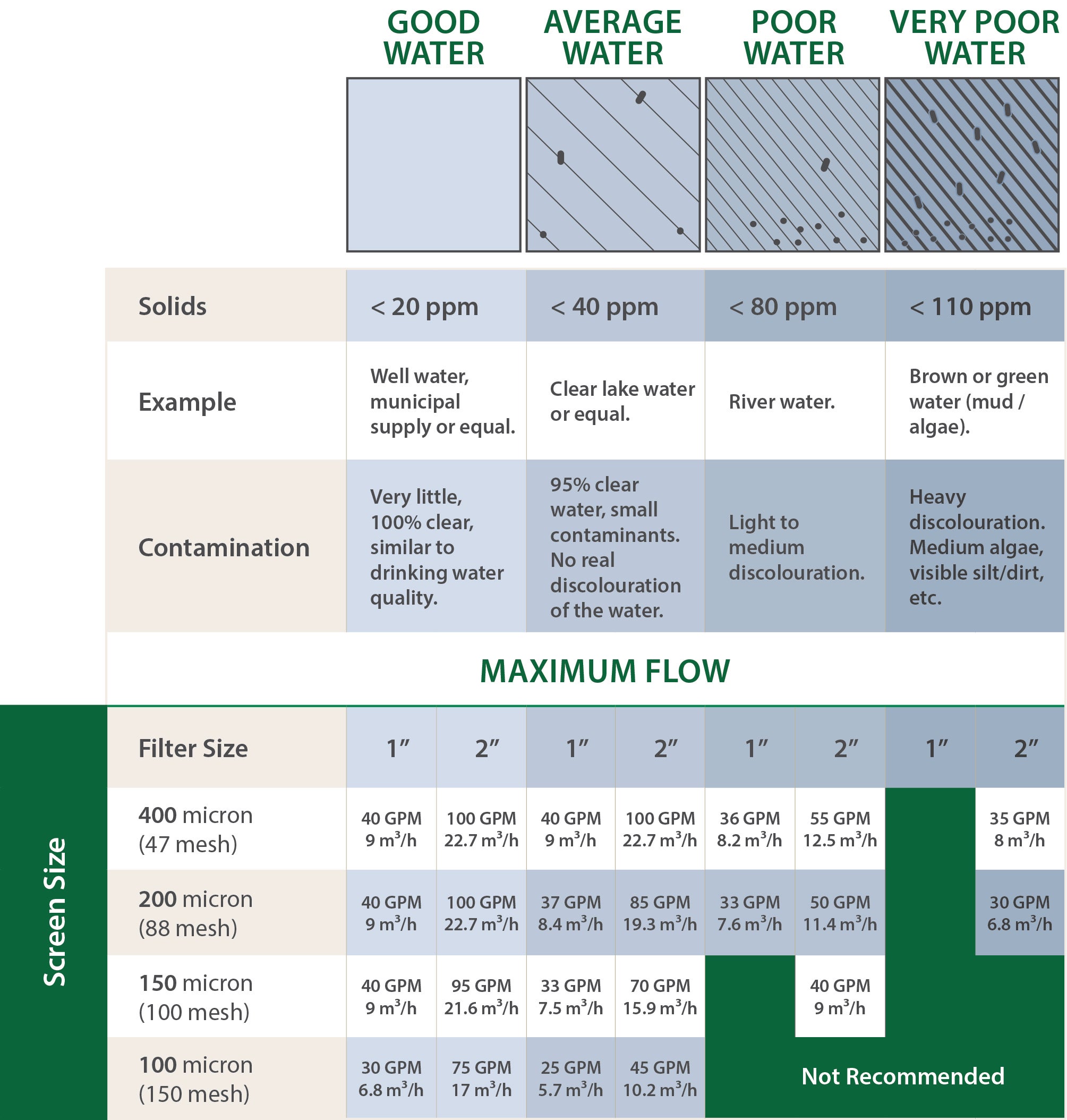

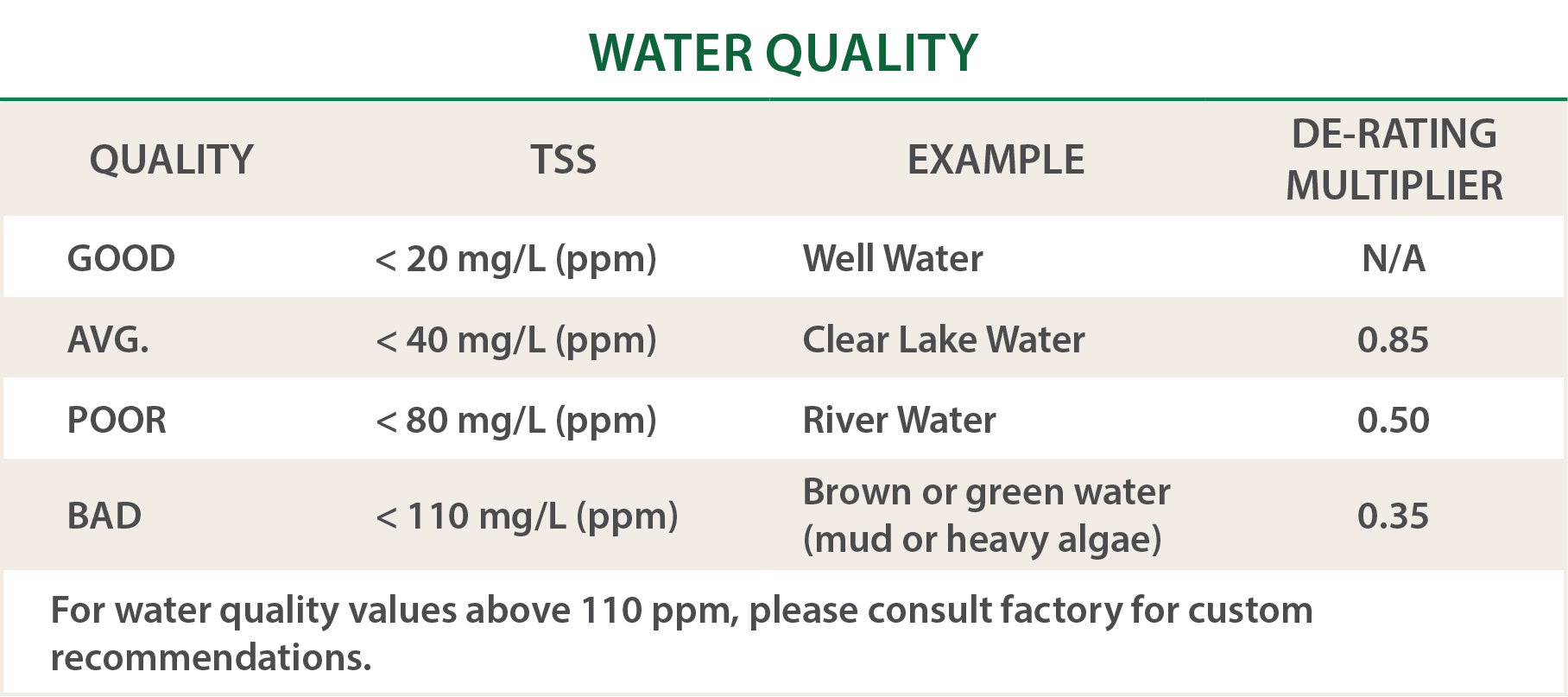

Ideally, A water particulate test should be conducted to determine the Total Suspended Solids (TTS) in your water. However, the following chart can be used as a guide to estimate your water quality.

Why does water quality matter? As water quality decreases, so does the maximum flow capacity of the filter. For example: A filter rated at 1000 GPM in good quality water would only be rated at 500 GPM in poor quality water.

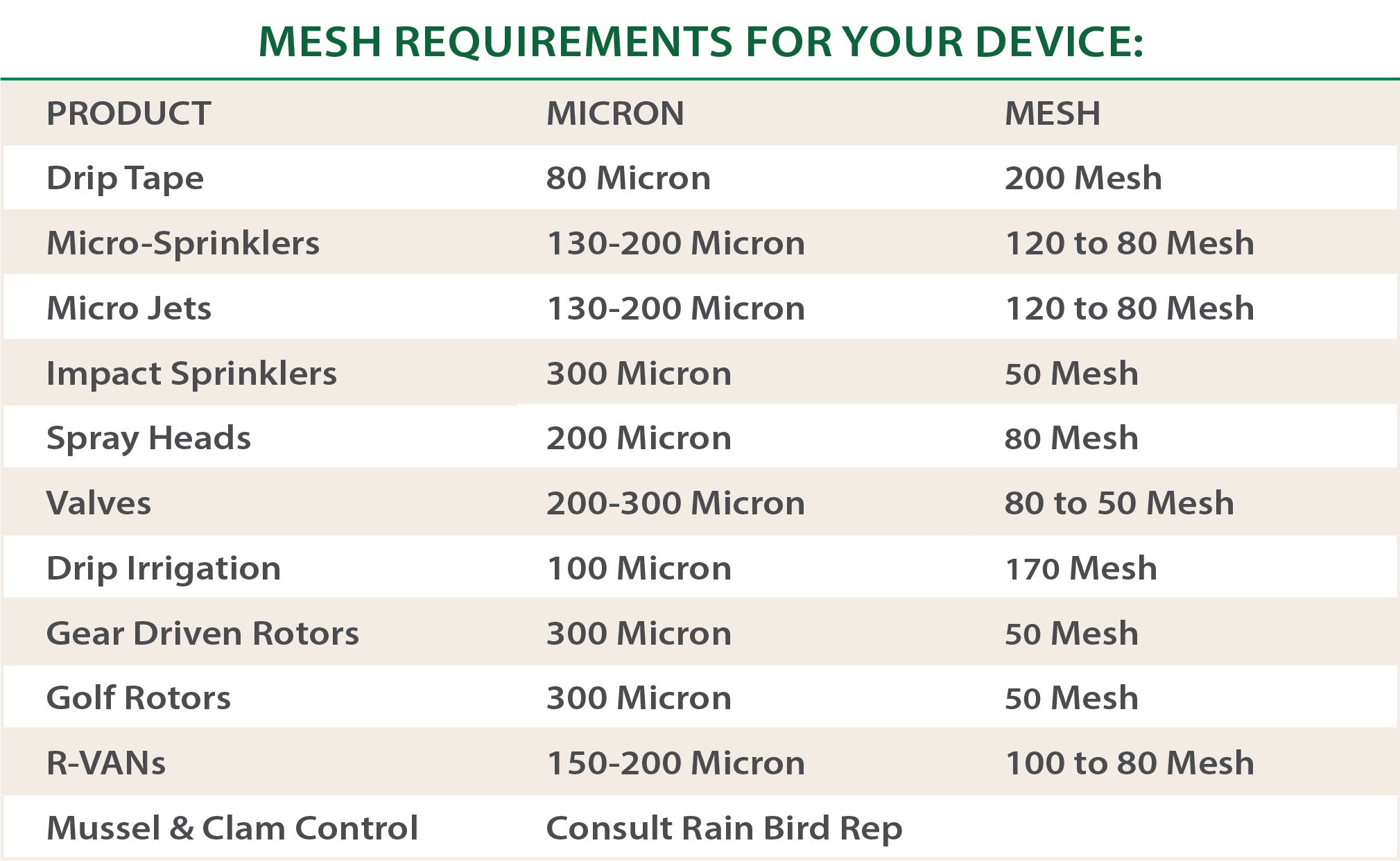

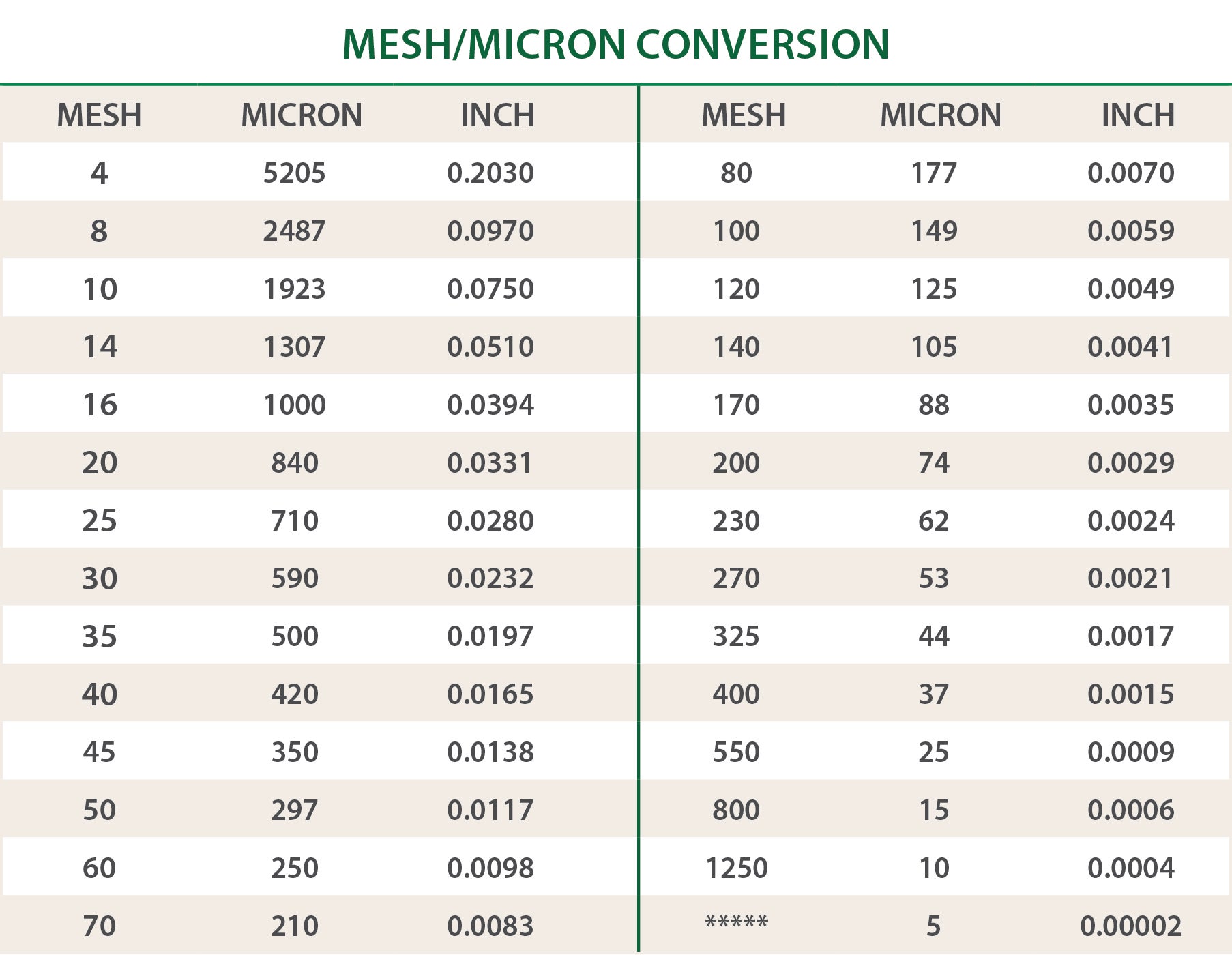

Each irrigation product has its own minimum filtration requirements. Products with smaller orifices will require finer filtration, which correlates to larger mesh.

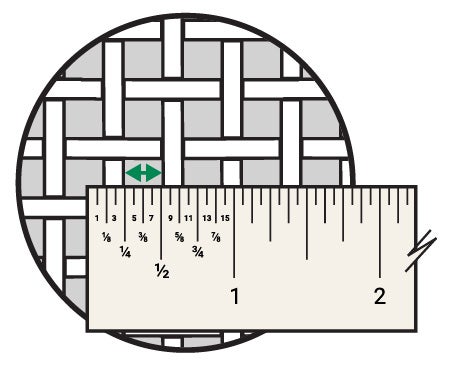

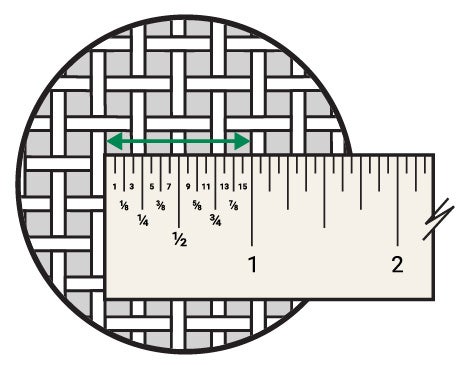

Defining "Micron" & "Mesh"

Measurement

Measurement

Don’t see your device? Find more mesh to micron conversions below:

Keep in mind the available space in relation to the space needed for a filter (vertical or horizontal orientation).

Disc Filters: Needs more space than a screen filter (perhaps double)

Screen Filters: Very space efficient. Space limitations may favor a G-Series over a Disc Filter

Centrifugal Separators: Very space efficient

Everything performs better with the proper filtration. Rain Bird offers a wide range of primary filters designed to keep clean water flowing and irrigation running smoothly. Email filters@rainbird.com or fill out our Filter Specification Form to find the right filter for your needs.

Explore Centrifugal Separators

CS Series Centrifugal Sand Separator

Explore Backwash Filters

G-Series Hydraulic Suction Scanning Screen Filter

I-Series Hydraulic Suction Scanning Screen Filter

HDF-Series Disc Filter

Every System Functions Better With Primary Filtration

Even the smallest contaminants can build up in nozzles, rotors, valves or other equipment, resulting in higher flow rates and more water needed to offset lost capacity. Blocks caused by debris can quickly cause costly damage to the system, the landscape and your reputation. Talk to a Rain Bird rep today to learn more about saving time, water, money and plant life—by stopping sediment at the source.