Irrigation Design Tips for Selecting the Right Sprays, Rotors and Drip Components

In this irrigation design tip, we’ll review the selection criteria needed to inform your decision on which spray, rotors, and/or drip components for the project.

Most of the selection criteria uses the site-specific information gathered or calculated in the earlier steps such as: water source, water pressure, soil type, climate and determining the irrigation requirement. Selecting irrigation components without first gathering this information is premature and can lead to an irrigation system that does not perform to meet the landscape’s requirements and can cause significant performance and maintenance problems.

In previous Irrigation Design Tips, we identified required information that you need to gather before the selection process begins. Here’s a quick review.

1. Water supply and pressure, and flow limit

Each type of component has a performance range for proper operation and these ranges must fit within the available flow and pressure criteria, both of which are a function of the water supply.

2. Climate

Areas with special climatic conditions will require special components. Windy areas may demand low-angle nozzles that keep the water near the ground where it resists being blown away. Landscapes in arid climates which experience excessive heat may need either higher flow nozzles or multiple irrigation cycles to maintain the plant material.

3. Soil type and terrain

The application rate cannot exceed the soil’s ability to accept water. Low precipitation rate (PR) nozzles may be required to adjust the rate of water application to the intake rate of the soil. Also, low PR nozzles or dripline can be used on slopes to reduce the potential for runoff and erosion.

Additional Considerations

In addition to any special request by your client or property owner, here are some additional points of consideration when selecting the right components for your project:

1. Size and shape of the areas to be watered.

The goal is to select the type of device that will cover the area properly using the least number of units.

2. Types of plant material to be irrigated also dictates which type of component is to be used.

Lawns, shrubs, trees and ground covers may all require different types.

3. Protection of hardscapes or other structures that can’t tolerate overspray.

4. Compatibility of the components used on the same valve.

Compatibility is particularly important when laying out laterals or circuiting sprinklers into groups that will be served by the same valve. You want to avoid mixing components with different precipitation rates on the same valve whenever possible. When components with varying precipitation rates are on the same valve, the owner or maintenance personnel are required to over water one area to sufficiently water another. Even the same type of components may require separate valves to match up water application rate with the rest of the components.

Using matched precipitation nozzles (MPR) allow the same type of sprays or rotors, no matter what arc they cover, to be circuited on the same valve and deliver the same precipitation rate.

MPR nozzles discharge proportional flows of water that match the arc or part of a circle they cover. A full circle nozzle discharges twice the flow of a half circle nozzle and a quarter circle nozzle discharges half of what the half circle unit does. Some nozzles, such as Rain Bird’s Rotary Nozzles have matched precipitation rate with 5000 MPR rotor nozzles – in this case you can use an 1800 Series spray with a Rotary Nozzle on the same valve as a 5000 rotor with MPR nozzle.

Performance Data

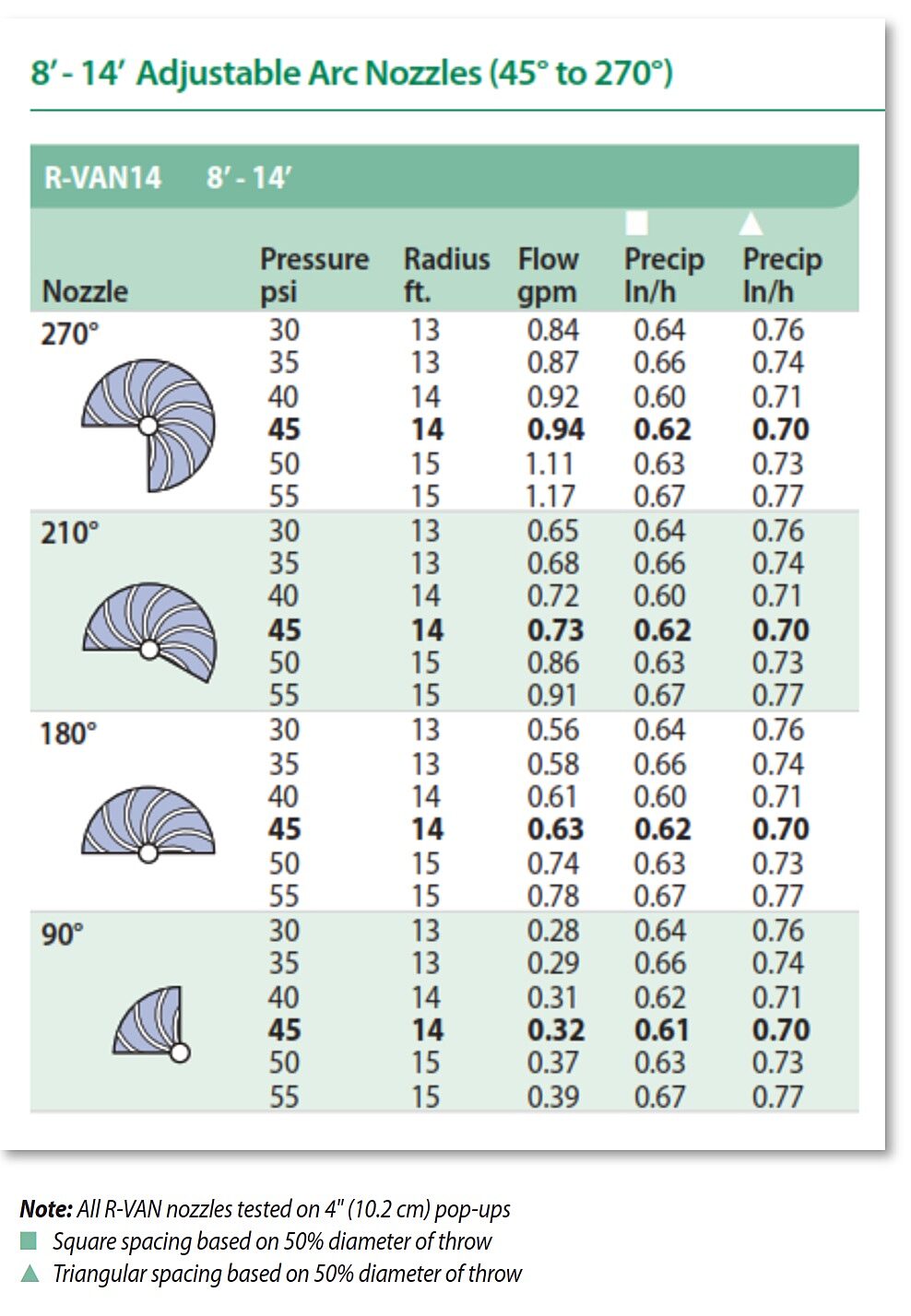

When looking for an irrigation component in a manufacturer’s catalog, the performance chart for the sprinkler contains several pieces of important information.

The arc or pattern of coverage is usually diagrammed for quick reference so the designer can see if the needed pattern is available in that series of nozzles. The model number of the component or nozzle is called out so it can be specified, by number, in the legend of the irrigation plan.

The operating pressure range of the unit is also noted so that the designer will know the pressure requirements for the performance desired. This range is usually the minimum to maximum pressures under which the nozzle will deliver good distribution of water throughout the entire area of coverage.

Another important number from a performance chart is the radius or diameter of throw. Usually given in feet (meters), this is the actual distance determined by the manufacturer’s testing at the various water pressures listed.

The discharge of the nozzle is given for each pressure noted in the chart. For most nozzles, the discharge is given in gallons per minute (meters cubed per hour or liters per second), and in the case of drip emitters, in gallons per hour (liters per hour). Knowing both the pressure and discharge requirements of the sprinklers is very important.

Also included is the precipitation rate. This is the water delivery rate in inches per hour (millimeters per hour) at particular spacing. The spacing is usually stated as a percentage of the diameter of the sprinkler’s coverage.

Now that you have collected all the data needed, choosing the right spray, rotor or drip emission device will come down to choosing the option that best satisfies design and operational goals.

This tip was excerpted from Rain Bird’s Irrigation Design Manual which has exercises you can take to help reinforce your understanding.